Ultra-stable Flow Control for Analytical Instruments

With our vast knowledge on the specific requirements of Electronic Pressure Control and Electronic Flow Control in GC applications we can help Gas Chromatograph manufacturers in building better products in a relatively short amount of time. This means you can get your products to market quicker, have unsurpassed analytical grade flow control and still keep product cost in check.

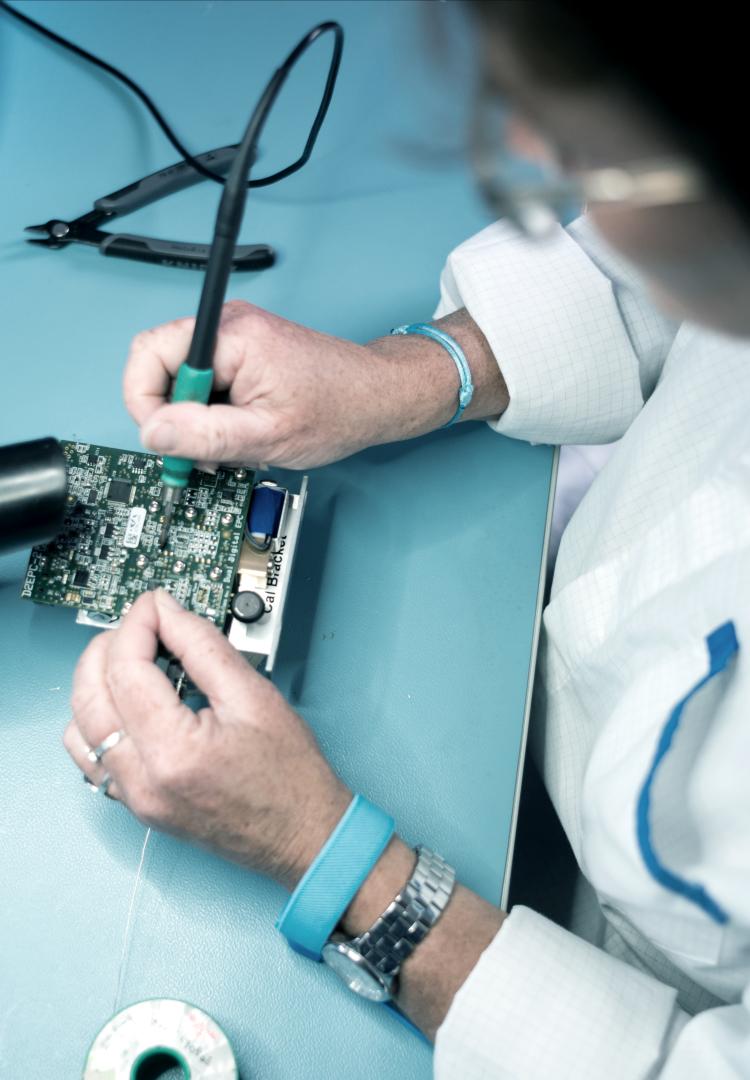

Our policy is to deliver exactly what the Instrument Manufacturer needs. We build quality and our knowhow into every derivative of our EPC Reference Design. By re-using the core EPC building blocks we can provide products that physically fit the application and have the required flow configuration in a relative short amount of time and with predictable results.

Features and benefits

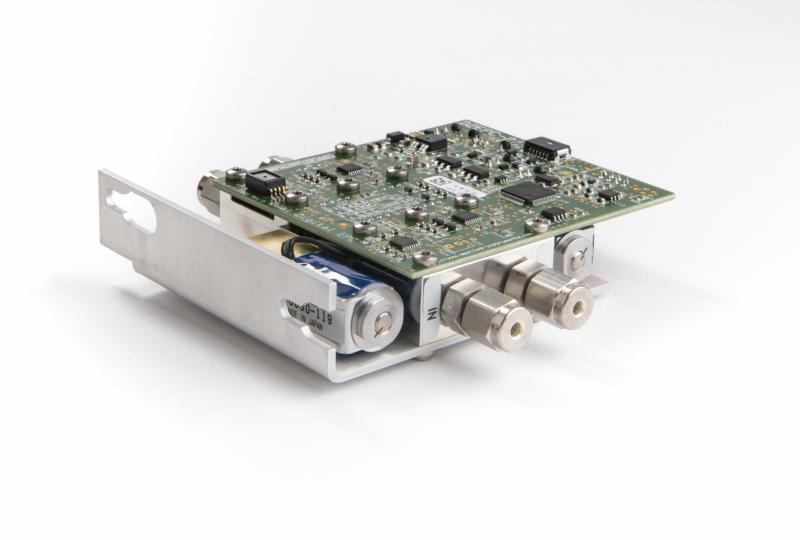

2 independent channels

Each channel can individually be setup for flow or pressure control

Factory calibrated for multiple gasses

Simple interfacing using RS485

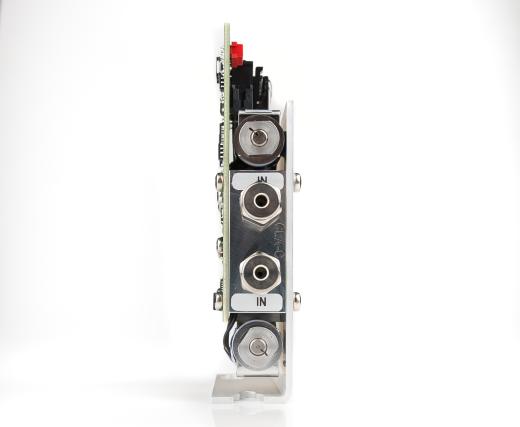

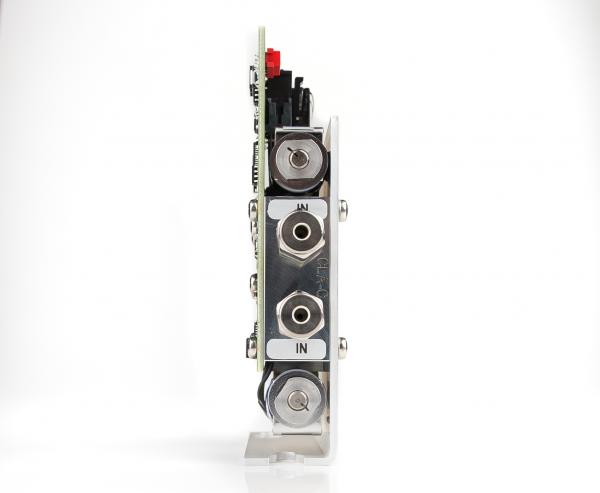

Ultra small footprint of 26 x 78 mm

Controlled using “real” values such as mL/min or kPa

Unique Design

The design of the D2EPC-2 is very flexible. By using a small and versatile manifold, without built-in restrictors, virtually every EPC configuration can be created using the same hardware.

This is how we do this:

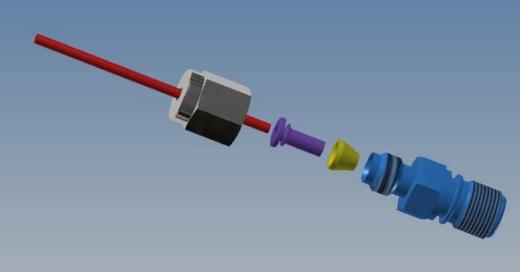

- Input and output restrictions are housed in screw-on tube fittings

- Flow control range is configured by using different restrictions in screw-on tube fittings

- Pressure control range is configured by using pressure sensors with appropriate range

- Manifold is identical regardless of flow or pressure channel choice

- Flow direction can be reversed because of symmetrical manifold

- Various tubing connection standards can be used due to screw-on fitting design

Reference Design

The D2EPC-2 is intended as reference design. This means that for large quantity production, special versions can be derived, using the same core technology. Physical size, communication protocols, number of channels may all be adjusted to your exact requirements. We are happy to discuss how we can fulfill your special requirements based on our core technology.